How do you hold additive parts for post-machining?

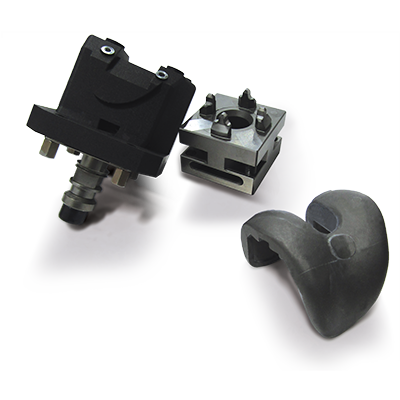

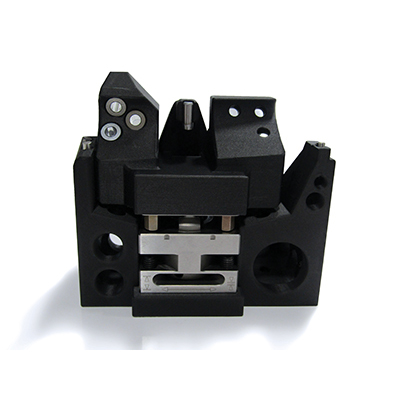

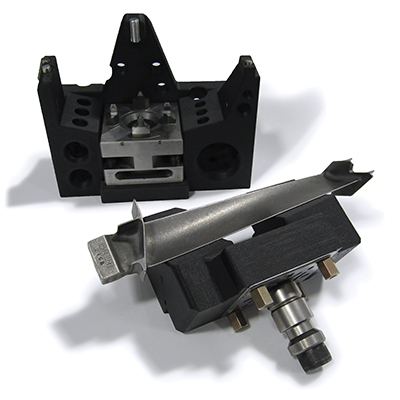

Blue Photon workholding products are designed to hold complexed-shaped, additive parts for tight-tolerance machining, and final finishing while creating better parts, and lowering manufacturing costs. To learn why we are the world’s solution to holding additive parts, check out the video below: