5/19/2020 | 4 Minute Read

Turning to an Adhesive for Lathe Workholding

“Adhesive cured by ultraviolet light is an option for securing parts for machining that could otherwise distort when traditional, mechanical clamping techniques are used.”

Check out the article from Production Machining Blog to learn how BlueGrip workholding adhesive could be a solution to your turning applications:

Turning to an Adhesive for Lathe Workholding

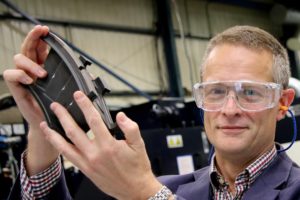

Thin rings such as this one are candidates for a photo-activated adhesive workholding process. The process eliminates part distortion that can might happen when conventional, mechanical clamping devices are used.

For some turning applications, chuck jaws or other conventional workholding devices for CNC lathes can cause a part to distort as clamping force is applied. This can be the case for large, thin rings such as the one shown on the left. Those workholding elements can also prevent full access to a part, which might necessitate reclamping for an additional operation.

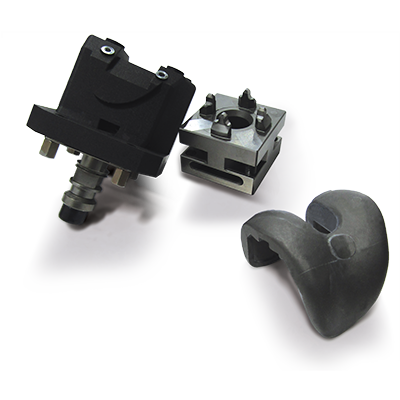

Blue Photon offers an alternate workholding method for these types of situations that uses adhesive cured by ultraviolet (UV) light to secure a part for turning. It can also be used for other processes such as milling, grinding, electrical discharge machining and 3D printing/additive manufacturing.

Read the rest of this entry »