Workholding Technology for High and Low Volume Machining

One of the challenges that is faced in today’s markets is the necessity of finding an efficient workholding method that can be easily introduced into a fully automated operation. Blue Photon’s patented adhesive workholding system can be easily implemented into most current production lines. Once the part is bonded to the transfer tool, the part can be quickly moved from one operation to the next while reducing the risk of inaccuracy during part transfer.

Blue Photon’s technology eliminates the need for multiple highly accurate fixtures which can save you time and money on fixture building. Blue Photon’s workholding system allows manufacturers to:

- Achieve tight tolerances

- Hold near-net shaped parts for machining

- Achieve five- or six-sided part access

- Implement easily into a fully automated production cell

- Reduce or eliminate part distortion

- Significantly reduce fixture building time and cost

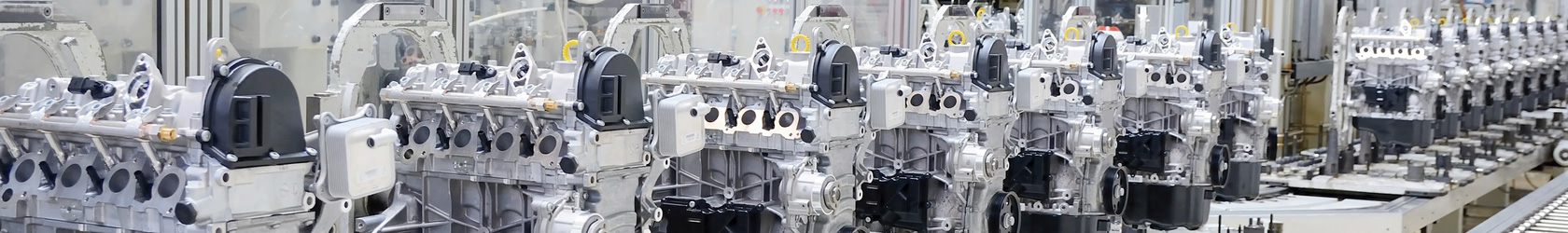

Does your high volume production company need assistance with workholding solutions? Blue Photon is ideal for automation.

Application Example

We currently have several Blue Photon users that have automated each of the steps of our workholding technology into robotic production lines, including part loading, application of adhesive, curing, removal and clean up. Please reach out to us to discuss your particular automation needs.

Contact us today to discuss how we can assist you with implementing our workholding technology into your automation processes.