Cleaning up the adhesive is simple.

Cleaning up the adhesive is simple.

Blue Photon offers a variety of soak tanks and cleaning tools to efficiently separate the workpiece and remove any cured residual adhesive from grippers and machined parts.

Contact us for more information about our cleaning equipment and methods.

Heated Soak Tank

Part#: 81312

The soak tank allows for debonding the part from the grippers without twisting. This method is preferred in applications where twist debonding could cause delamination or other damage to the workpiece.

Features*

- Stainless steel construction.

- Insulated tank with tap.

- Easy access for cleaning and maintenance.

- High performance insulation to avoid heat loss.

- Easy fill and drain tank.

- Low energy consumption.

- Controlled temperature.

- 5″ interactive full-color touchscreen.

- Programmable temperature control/sensor.

- Simple push button cycle operation.

- Bluetooth / Wifi connectivity.

Product Specifications

- Immersion platform size: 23 x 20″ (584 x 508 mm)

- Immersion depth: 8″ (203 mm)

- Cycle time: up to 99 h

- Temperature range: 41°F – 203°F

- Capacity: 14 gal. (56 L)

- Electrical: 120V / 50-60 Hz / 1 – (12 A)

- External dimensions: 26 W x 23.6 D x 20.65 H inches

- Crated dimensions: 680 x 660 x 320 mm

- Weight: 43 lb (19 kg)

Optional

Insulated Tank Lid

Stainless steel lid with handle for preventing water evaporation during heating process.

Part #: 81309

Floating Balls

The floating balls are ideal for avoiding evaporation during the heating process.

Part #: 81310

Features

- Hollow plastic floating balls, 20 mm diameter.

- Made of polypropylene.

- Create a blanket of insulation in any open bath,

- reducing heat loss and evaporation.

- Reduce fumes and splashing hazards.

- Can be used in temperatures up to 110°C / 230°F.

*All external walls of the unit are insulated to help protect from hot surface contact. All specifications subject to change.

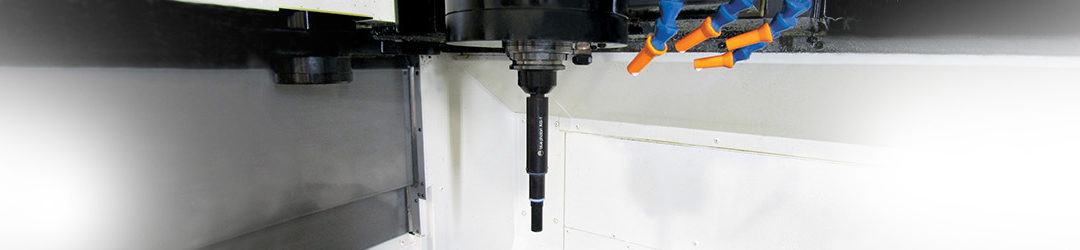

CNC Spindle Mounted Cleaning Tool

Part#: 82400, 82500

The spindle mounted gripper cleaning tool loads in a CNC machine to remove cured adhesive from grippers.

Part #: 82400 – Gripper Cleaning Tool Assembly

Part #: 82500 – Replacement Head

Features

- Mounts in any 3/4″ diameter collet or end mill holder.

- Replaceable head for P/N 82400 tool assembly.

- Cleans an estimated 1,000 grippers before replacing head.

- Do not use with corrosion resistant grippers.

Pressurized Steam Cleaner

Part#: 84750

The steam cleaner provides pressurized steam continuously to easily remove residual cured adhesive from grippers and workpieces. Economical solution for prototypes or low-volume usage.

Features*

- Steam lock for continuous steam cleaning action.

- Steam ready indicator.

- Product dimensions: 10.5″ x 10.5″ x 9.5″

- Product weight: 9 lbs

- Hose length: 6.6′

- Power cord length: 16′

- Power: 120V, 12.5 A, 1500W

- Steam temperature: up to 275˚F

- Steam pressure: 50 psi (approx.)

- Water tank capacity: 54 oz

- Heating time: 8 mins.

- Cleaning time: up to 50 mins.

*Actual unit may vary from one shown.

Heavy Duty Steam Cleaners

Part#: 84870, 84880, 84881, 84890

These heavy duty steamers produce 60 PSI for increased of continuous steam pressure, and reaches temperatures up to 221°F at the tip. These steamers are ideally suited for cleaning away cured adhesive on grippers and parts.

Part #: 84870 – Approximately 6 hours of working time.

Features

- 110V/120V 1200W heating element

- 1.25 gallon, 4.5 liter water capacity

- Low water light indicator

- 61 PSI, 4.1 bar operating pressure

- Pressure/safety switch

- 30A heavy-duty contactor

- 12-gauge heavy-duty wiring

- Stainless steel tank and outer casing

- Carrying handle

- 15-20 minute heat up time

Part #: 84880 – Minimum 8 hours of working time.

Features

- 110V/120V 1200W heating element

- 2.37 gallon, 9 liter water capacity

- Visual water level indicator

- Low water light indicator

- Uses regular tap water

- Ranco pressure control/li>

- 12-gauge heavy-duty wiring

- Stainless steel tank and outer casing

- 2 incoloy heating elements (1-spare)

- Carrying handle

- 30-40 minute heat up time

- Optional 220V (P/N 84881) available to order.

Part #: 84890 – Full-time steam.

Features

- 110V/120V

- Automatic shut-off of pump in case water supply is interrupted

- Boiler thermostat reset switch

- Heavy-duty adjustable feet

- Low water light indicator

- Uses regular tap water

- Ranco pressure control

- 12-gauge heavy-duty wiring

- 1 Incoloy heating elements

- Stainless steel tank and outer casing

- Blow down valve

- 20-30 minute heat up time

- 20-amp service supply required

- Direct connection to a water supply line

Scrapers

Part#: 80030, 86004, 86005

The scraper is used to clean parts and grippers of cured adhesive after heating.

Part # 80030 – 5″ aluminum handle knife with a heavyweight adhesive removing blade.

Part # 86004 – 3/4″ flat edge nonmarring plastic scraper.

Part # 86005 – 7/8″ flat edge nonmarring plastic scraper.

| Part # | Description | Application |

|---|---|---|

| Cleaning Equipment | ||

| 81312 | Heated Soak Tank | Stainless steel heated soak tank for debonding, cleaning parts and grippers of cured adhesive. |

| 82400 | Gripper Cleaning Tool Assembly | Loads in CNC machine spindle to remove cured adhesive from grippers. |

| 82500 | Replacement Head | Replacement head for P/N 82400. |

| 84750 | Pressurized Steam Cleaner | For removal of cured adhesive from workpiece and/or grippers. |

| 84870 | Heavy Duty Steam Cleaner - Approximately 6 hours of working time | Hot water pressurized spray used to remove cured adhesive, stainless steel. |

| 84880 | Heavy Duty Steam Cleaner - Minimum 8 hours of working time | Hot water pressurized spray used to remove cured adhesive, stainless steel. |

| 84881 | Heavy Duty Steam Cleaner (220V) - Minimum 8 hours of working time | Hot water pressurized spray used to remove cured adhesive, stainless steel. Optional 220V available to order. |

| 84890 | Heavy Duty Steam Cleaner - Full-time steam | Automatic hot water pressurized spray used to remove cured adhesive, stainless steel. |

| 80030 | Aluminum Scraper & Blade | Cleans part and grippers of cured adhesive after heating. |

| 86004 | 3/4" Flat Edge Plastic Scraper | Cleans part and grippers of cured adhesive after heating. |

| 86005 | 7/8" Flat Edge Plastic Scraper | Cleans part and grippers of cured adhesive after heating. |