Turning

Turning

Blue Photon’s patented adhesive workholding technology is the perfect solution for holding delicate workpieces that are prone to distortion in the turning process. Parts such as large, thin rings are easily held in place with Blue Photon without the distortion that is caused with many other workholding methods while turning. Eliminating the need to reposition clamps or relying on operators to “gently” clamp the part can be eliminated. Consult the factory on turning applications.

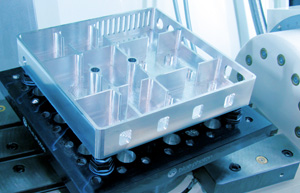

Additive Manufacturing

Additive Manufacturing

It is estimated that over three quarters of all parts that are 3D printed require some type of post process machining. Finding a workholding method that can accommodate these net shaped parts can be a serious engineering challenge. Blue Photon’s advanced workholding technology is ideal for these net shaped (sometimes very complex) parts. Inexpensive fixtures can be designed and built quickly. Avoiding the need to print clamping lugs adds up to tremendous savings, especially when expensive or exotic materials are involved.

EDM

EDM

Blue Photon’s workholding system can aid part clamping in electrical discharge machining (EDM) and eliminate cumbersome fixtures with moving parts that can get gummed up in the EDM machine. The system is especially helpful when the part needs to be uploaded into the fixture. Shim checking can be completely eliminated when a zero point system is used in conjunction with Blue Photon’s workholding.

Grinding

Grinding

Blue Photon is the ideal workholding solution for creep and surfacing grinding applications. One of the unique benefits of the BlueGrip™ workholding adhesive is its vibrational dampening quality. BlueGrip can actually absorb some of the vibration that is common in grinding, thereby reducing chatter. Reducing chatter can help to achieve tight tolerances and enhance surface finishes. When coupled with a zero point workholding system automated part load becomes simple. Another unique benefit of Blue Photon which makes it ideal for grinding is its ability to allow fixtures to be designed and built for excellent coolant placement. This is especially important in the grinding industry, where coolant placement can be critical.

Milling

Milling

Whether you are aggressively milling materials like titanium, stainless steel, or superalloys, or doing finish work on a complex part, Blue Photon is your workholding solution. Thousands of parts have been successfully milled using Blue Photon’s workholding technology, confirming its ability to withstand heavy milling forces while simplifying the workholding portion of part processing. Reduced labor, time, and scrap are often realized. Blue Photon can be used with virtually all materials that are found in the manufacturing industry today. With the Blue Photon system, clamping induced distortion from over-tightening clamps can be eliminated.

5-Axis

5-Axis

Finding a workholding solution that will allow you to reap the full benefits of a 5-axis machine can be a challenge. Most traditional workholding systems used with net shaped parts will have tool interference issues when used on a 5-axis machine. With Blue Photon’s workholding adhesive solution, you can configure the grippers in a placement that will maintain the necessary clearances around the workpiece, allowing for five and sometimes six-sided access to the part. When used with billet material, dovetails and edge clamping can be eliminated.