Shape, materials, and the challenges that lay ahead.

Modern digital design and manufacturing, along with material science breakthroughs, have enabled an extensive array of new products and machines. New technologies developed a decade ago are now beginning to find their way into mainstream manufacturing, with the most significant of these being additive manufacturing (AM) and the introduction of new composite materials. In many cases these new methods and materials cause manufacturers to scratch their collective heads when it comes to machining these parts.

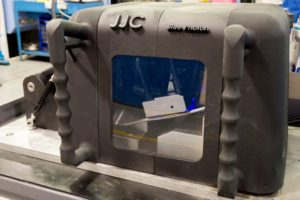

Precision Grinding and Manufacturing uses an atypical means to fixture thin parts that are prone to flexing when conventional workholding clamps are used: adhesive cured by UV light. -By Derek Korn

Precision Grinding and Manufacturing uses an atypical means to fixture thin parts that are prone to flexing when conventional workholding clamps are used: adhesive cured by UV light. -By Derek Korn Let’s say you want to machine your initials on your favorite Hummel figurine or cut the likeness of the school mascot on your daughter’s Little League helmet. How are you going to grip them? A conventional way to grip fragile, difficult-to-hold workpieces is to encapsulate them in some sort of potting compound, a time-consuming and wasteful process.

Let’s say you want to machine your initials on your favorite Hummel figurine or cut the likeness of the school mascot on your daughter’s Little League helmet. How are you going to grip them? A conventional way to grip fragile, difficult-to-hold workpieces is to encapsulate them in some sort of potting compound, a time-consuming and wasteful process.

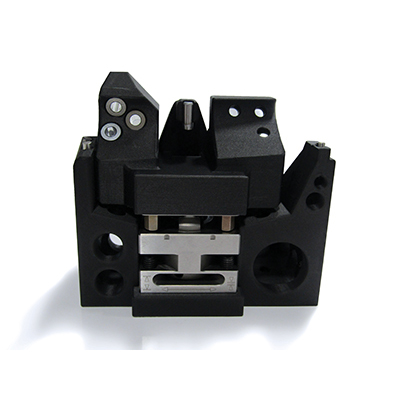

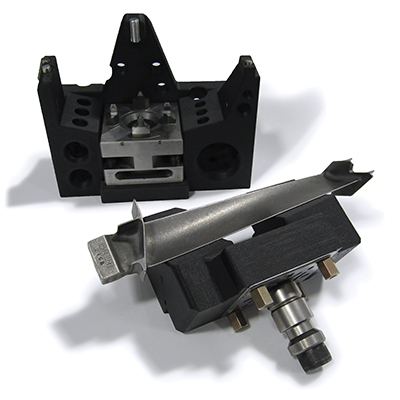

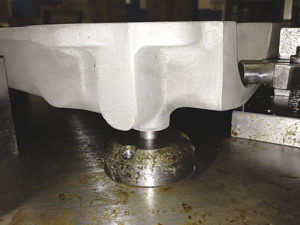

A new method for securing a turbine blade prior to machining by gluing one side of its aerofoil to a fixture, rather than using mechanical clamping, allows the root and tip to be ground in one operation. Traditionally, due to clamp interference, at least two operations are required on conventional CNC grinders to machine the fir-tree and wedge face on the root as well as the shroud end features at the tip.

A new method for securing a turbine blade prior to machining by gluing one side of its aerofoil to a fixture, rather than using mechanical clamping, allows the root and tip to be ground in one operation. Traditionally, due to clamp interference, at least two operations are required on conventional CNC grinders to machine the fir-tree and wedge face on the root as well as the shroud end features at the tip.